Offshore Tooling

After extensive research Tri-Way Mold & Engineering has linked with several reputable overseas mold builders in order to provide our customers with the option of having Tri-Way expertise of managing all aspects of the mold build from design through final approval at overseas pricing.

Learn More About Offshore ToolingProduction Molds

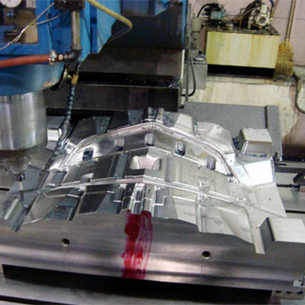

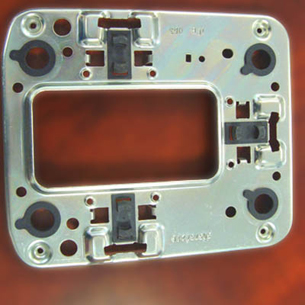

Tri-Way Mold & Engineering has over 35 years' experience building high quality, tight tolerance injection molds, utilizing high speed CNC machining and orbital & wire EDM, from design through final approval. All types of molds ranging from electrical connectors to interior & exterior trim parts up to 1,500 ton press size.

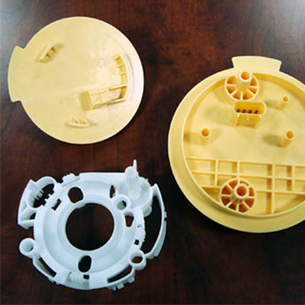

Learn More About Production MoldsPrototype Molds

Tri-Way also excels in the construction of simple or complex steel or aluminum prototype molds. Using our advanced CNC and CAD/CAM technology and "lights out" operation, we are to implement the necessary speed and quality required for the successful completion of your project.

Learn More About Prototype MoldsRepair & Maintenance

Tri-Way Mold & Engineering understands the need for prompt and efficient service to your injection mold in the event of a breakdown or during scheduled preventative maintenance. We have an entire department, both day and night, dedicated to the transport and servicing of molds up to 45,000 lbs

Learn More About Repair & MaintenanceShort Run Molding

We use our 150-ton Plastar and 170-ton Van Dorn molding machine for tryouts and short production runs. We work with our customer to ship parts both domestically and internationally.

Capabilities

With our latest computer hardware and software technology, our high-speed CNC equipment, and CNC EDM we can machine to a near no bench finish.